TRAY PACKER FEATURED SOLUTIONS

– TRAY PACKING AUTOMATION CASE STUDIES–

Shelf-ready packaging provides numerous advantages to our clients and their resellers, and it all starts with a good packaging line. Well-chosen secondary packaging can help businesses increase their revenue by up to 35%. Besides that, good secondary packaging can make in-store logistics more efficient and economic, causing even the resellers to embrace and support the certain product.

If you have made a decision to make your secondary packaging shelf-ready, check out Tishma Technologies Tray Packers, available with accumulation conveyors, tuck and glue closing, user-friendly HMI operator interface and small overall footprints.

Case studies listed below showcase custom projects we did for different clients within Food and Home Care Industries.

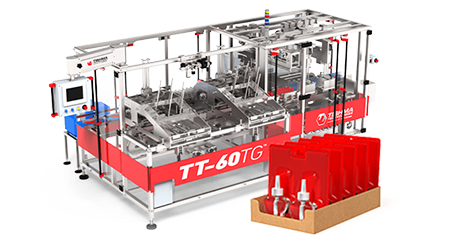

TT-60TG HIGH-SPEED TRAY PACKER FOR BLISTERS

The TT-60TG high-speed tray packer is an intermittent motion high-speed blister tray packer that can reach speeds up to 35 trays per minute. Designed and built for blister tray packing, it is perfect for display packaging and shelf-ready packaging of air freshener plug-in blisters, soap blisters, and similar household products.

TT-1300 CASE AND TRAY PACKER

FOR CARTONS

The TT-1300 is an intermittent motion Case and Tray Packer that can reach speeds up to 30 trays per minute. It is designed and built for packaging of candy cartons onto display trays that are further packed into a case. This piece of packaging equipment is available with different coding and labeling options and it is perfect for shelf-ready packaging of any product that is primarily packed in a carton. This system can be integrated with Cartoner, Pouch Machine or Palletizer for full end-of-line packaging solution.