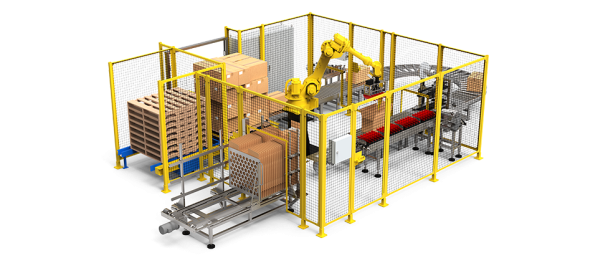

TT-1400RELP Robotic Case Erector, Loader and Palletizer

The TT-1400RELP is a Robotic Top Load Case Packer and Palletizer that can reach speeds up to 2 cases per minute. The robotic arm with specific EOAT is utilized for case erecting, case loading, and palletizing applications, which makes this solution ideal for a business that values flexibility and compactness over speed. Designed and built for case packing of stand-up pouches, this particular model is perfect for the casing of any pouch-packed product, whether it’s coffee, flour, sugar, candy, or stick packs.

Literature