CASE PACKER MACHINE FOR JUGS AND BOTTLES

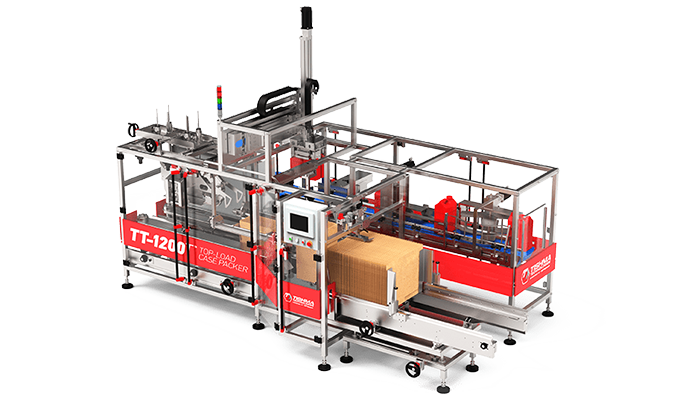

The TT-1200T is an intermittent motion top load case packer. It can reach speeds up to 20 corrugated cases per minute, and it is designed and built for the casing of jugs and bottles. With a completely automated sequence of operations, TT 1200T provides automation of case erection, case loading, and case sealing processes. TT-1200 can handle any jug type present on the market: gallon jugs, wide mouth rectangular bottles, handle jugs, f-style jugs, slant handle jugs… This piece of packaging equipment allows for quick and efficient secondary packaging of liquid containers filled with consumable liquids like milk, juice, or wine, or industrial and chemical liquids like various oils, detergents, acids, fuels, fertilizers, etc.

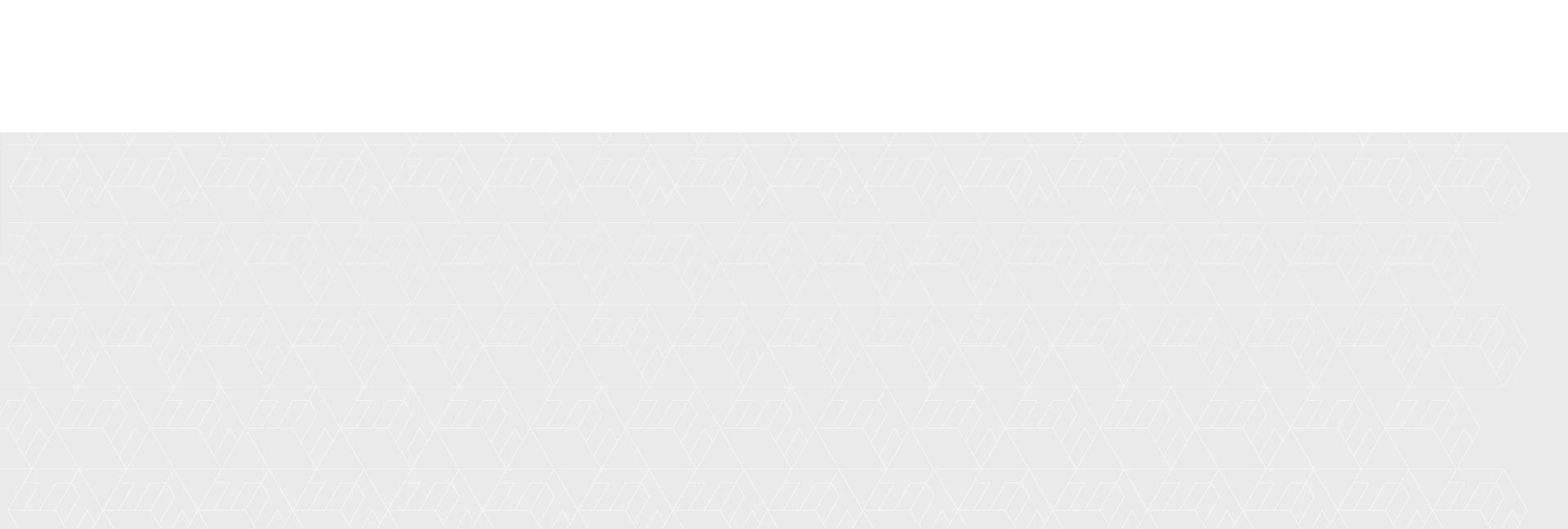

PRODUCT CASE PACKING PROCESS

TECHNICAL

SPECIFICATION

| TYPE | Top Load Case Packer |

| SPEED | Up to 16 CPM |

| CARTON MAGAZINE | 36+” powered magazine with positive carton erector |

| CASE LOADING | Pick And Place Gantry Device |

| CASE CLOSING | Tape Closing System |

| CONTROLS | Allen Bradley PLC/Drive |

TT-1200T TOP LOAD CASE PACKER OPERATION

Filled and sealed bottles are received with the cap side leading, or with the short dimension leading for the bottles with no handle. Bottles enter into the orientation and collation stations where they are arranged in the required pattern and then advance into the loading station. Case magazine feeds corrugated cases to the system using a gear-driven reciprocating feeder with vacuum-assisted case suction cup placers. The feeder incorporates a Venturi-style vacuum with monitoring gauges. Dual pumps assure consistent vacuum pressure at the case pick-off and setup point. RSC cases are erected and advanced to the case loading station. Pick-and-place gantry device picks the previously collated bottles and places them into the box. Filled cardboard cases progress into the case closing system, where a series of stationary plows and mechanical tuckers close the case flaps. Cases are sealed with two taping systems. Finished cases are discharged on a discharge conveyor.

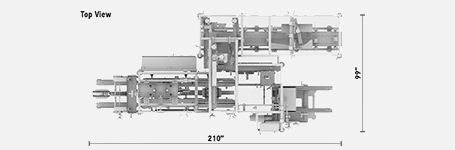

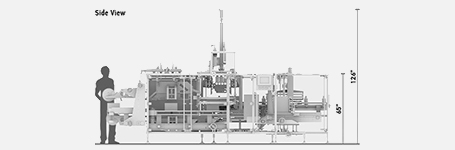

DIMENSIONS & FLOOR PLAN

TT-1200T features compact overall footprint so you can rest assured it will fit your floor space.

Reliable and portable with simple operation and user friendly interface, TT-1200T will be up and running in no time.

Built from welded tubular stainless steel with hinged cover panels and safety electrical interlocks, TT-1200T is powerful and efficient case packer that meets the highest standards with state-of-the-art simplicity.

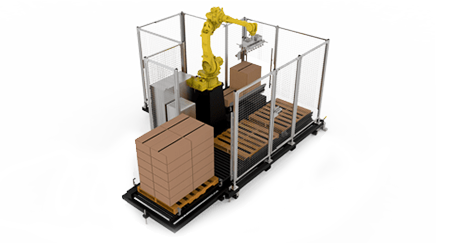

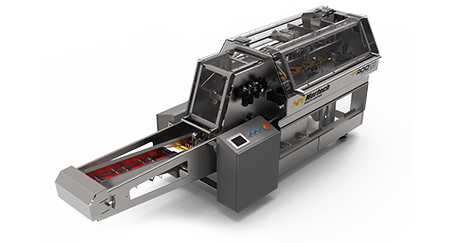

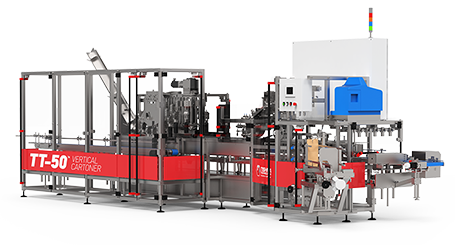

CAN BE INTEGRATED WITH