COLLATING AND BUNDLING FOR PHARMA PRODUCTS

All Tishma Technologies Cartoners and Case Packers can be integrated with an automatic ultrasonic

or heat sealing banding station which provides product bundling flexibility.

These bundling stations are fast, zero-pressure, zero-damage solutions that won’t compromise the

integrity of your sensitive medical or pharmaceutical products.

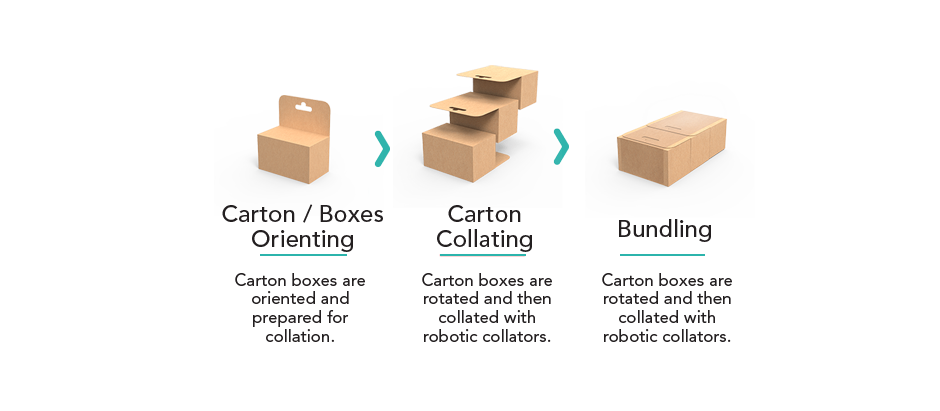

BUNDLING PROCESS

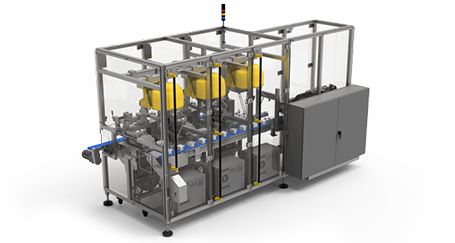

RAPTOR BUNDLERS

The Raptor and Raptor-R series bundling system is a total solution for all your wrapping and banding needs. Benefits and advantages of these bundling packaging machines are easy integration into existing packaging lines and quick bundling of most standard products.

This banding and wrapping machine can be used with cartons, bottles, trays, and more. Raptor and Raptor-R can be found in two different models – robotic and non-robotic.

The key features of this bundler machine are collation and aggregation with various banding and wrapping styles, compact and efficient footprint, and easy integration into existing packaging lines, without sacrificing valuable space and time.

Besides the bundling process, Raptor and Raptor-R can be customized for labeling, serialization, and data management with all your products.

Available with integrated servo-controlled collating devices.

Available with integrated robotic collating devices.

Available with integrated banding station

Bundling pattern flexibility according to your needs.

BUNDLING MACHINE

ROBOTIC BUNDLER RAPTOR-R

Raptor and Raptor – R can be easily integrated into the existing packaging line and can be used with cartons, bottles, trays, and more. These bundling machines are fast, zero-pressure, zero-damage solutions that won’t compromise the integrity of your sensitive medical or pharmaceutical products. The Raptor machines are also a perfect companion for any of our cartoning systems. Packed and discharged cartons can be collated and stacked and then banded or strapped in virtually any pattern.

SAFETY AND QUALITY PROCEDURES

In order to be considered client-ready, every machine has to go through a set of checklist-based tests. Transparent testing documentation and clear testing criteria ensure machine compliance with all necessary requirements. No machine “leaves” Tishma Technologies without passing all the tests.