PHARMA AND NUTRACEUTICAL BOTTLE CARTONING AND CASE PACKING AUTOMATION

Tishma Technologies’ vertical and horizontal cartoners and case packers offer precise and superior product handling, which makes them an ideal solution for secondary packaging of cosmetics, nutraceutical or pharmaceutical bottles. Our machinery can handle plastic and glass bottles of any shape: wide mouth bottles, oblong bottles, modern round bottles, boston round bottles, flat oval bottles, pharma cylinders, pharma packers, indented label bottles, recessed panel bottles, etc. Bottles are automatically loaded into the machine and then placed horizontally in a product holder or vertically directly into the carton or a case. Each cartoning and case packing machine is available with various printing and labelling add-ons which are pretty crucial in the pharma industry due to recent track-and-trace laws and demands for serialization. Leaflet and additional product component inserting is also an option.

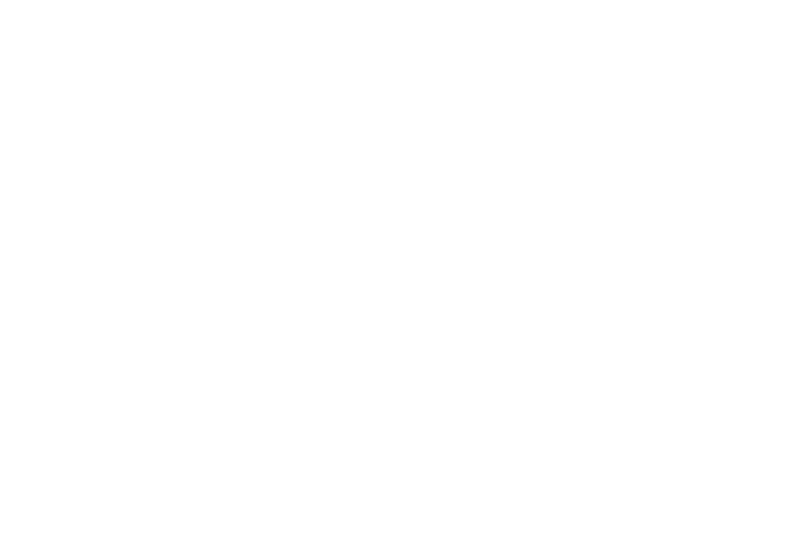

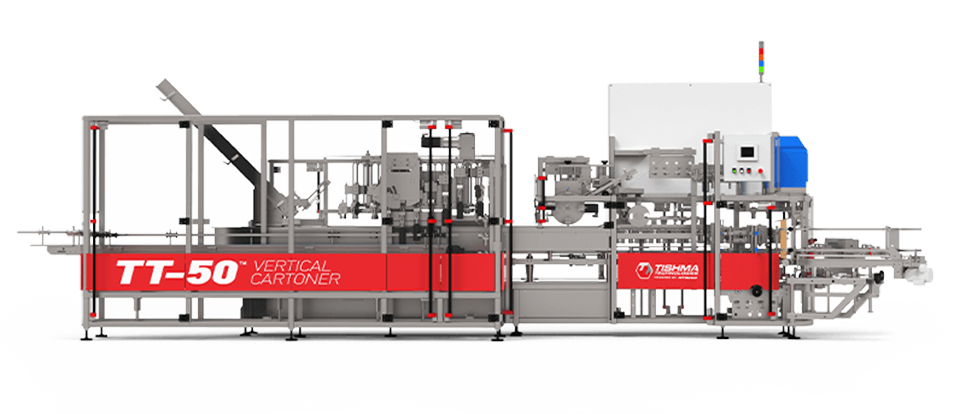

TT-50 Top-Load Manual Cartoner For Dosing Droppers

| TYPE | Top Load Cartoner |

| CARTON FEED | 36+’’ powered magazine with rotary carton feeder |

| CARTON LOADING | Manual, automatic bottle loading, or count/weigh scale interface |

| CARTON CLOSING | Straight or reverse tuck and/or hot melt glue |

| TOOLING | Available for tuck, glue, header, gable, flip-top and hex style carton styles |

| CONTROLS | Allen Bradley PLC’s and electrical components |

| DIMENSIONS | Width: 100″ Length: 168″ Height: 79″ |

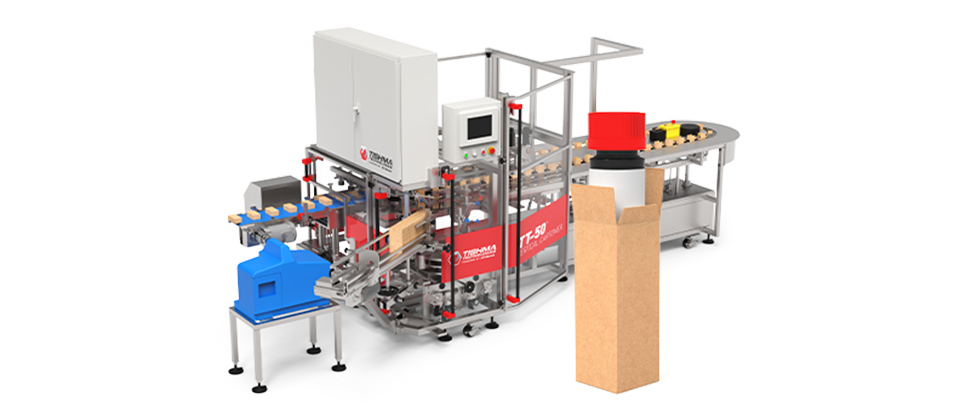

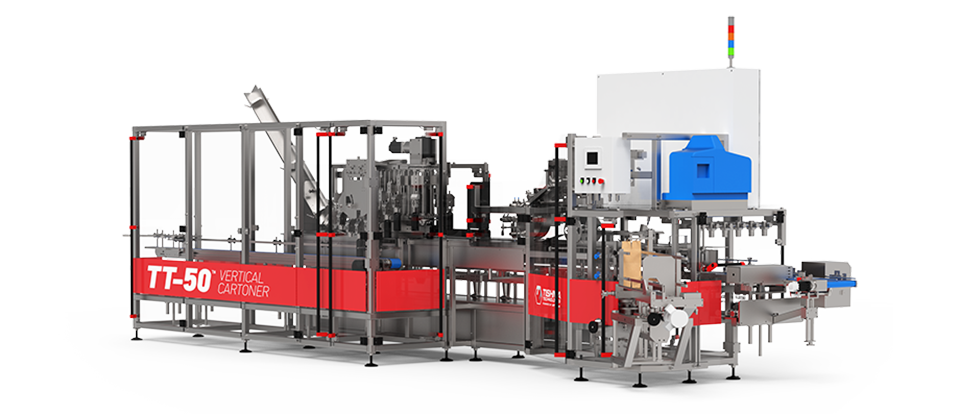

TT-50 Top-Load Cartoner For Hair Product Bottles

| TYPE | Top Load Cartoner |

| SPEED | Up to 140 CPM |

| CARTON FEED | Powered magazine with rotary carton feeder |

| SPEED | Variable to 30 TPM, depending upon application |

| CASE FEED | Powered magazine with reciprocating feeder. |

| CARTON LOADING | Automatic bottle loading |

| CARTON CLOSING | Glue Carton Closing |

| TOOLING | Available for tuck, glue, header, gable, flip-top and hex style carton styles |

| CONTROLS | Allen Bradley PLC’s and electrical components |

| SAFETY | Machine guarding with hinged stainless steel framed polycarbonate panels with latches and interlock safety switches |

| OPTIONS | Leaflet feeders, laser or inkjet printers, labellers, tamper evidence, embossers, visual verification and rejection systems |

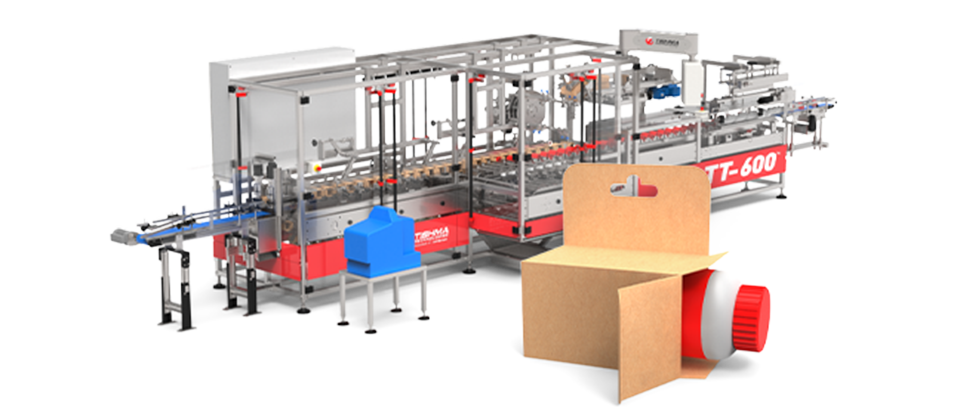

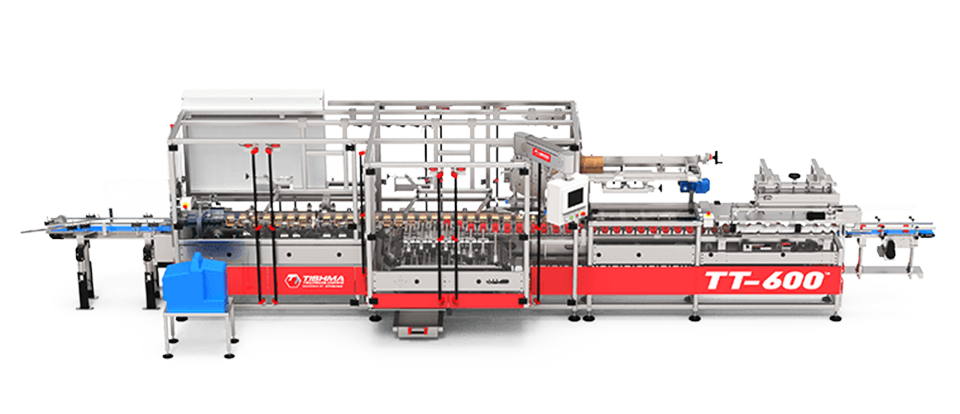

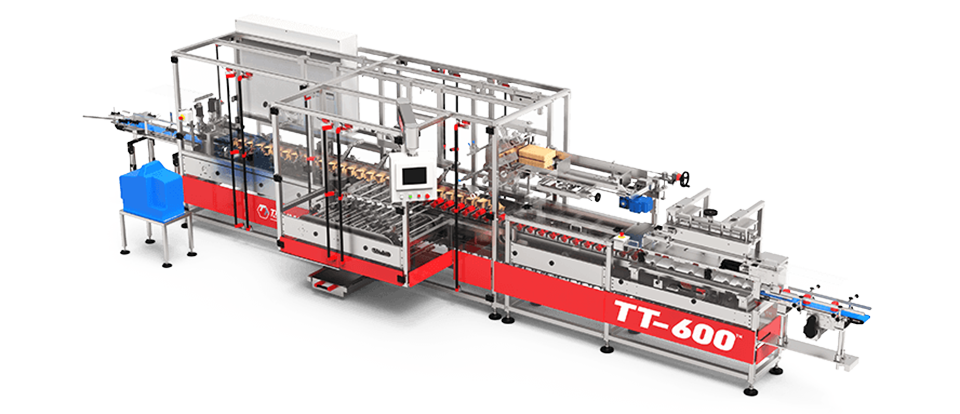

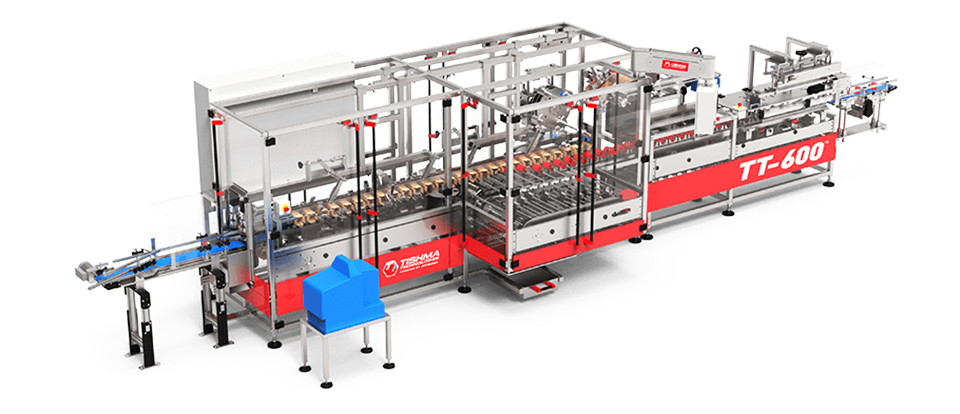

TT-600 Side-Load Cartoner For Pharma Bottles

| TYPE | Side Load Cartoner |

| MODE | Continuous Motion |

| CENTERS | 1.875″ to 16″ depending upon model |

| SPEED | Variable to 500 CPM, upon model and application |

| CARTON FEED | Powered carton magazine and rotary carton placer |

| PRODUCT INFEED | Lugged Incline Infeed Conveyor |

| PRODUCT LOADING | Article buckets articulate in to carton score lines |

| SENSING SYSTEMS | No product/ no carton and no carton/ no load (with automatic product discharge) |

| CARTON CLOSING | Straight or reverse tuck, or hot melt glue |

| FRAME | Welded tubular stainless steel of open, sanitary design |

| DRIVE | Servo driven with line shaft |

| CONTROLS | Allen Bradley PLC and components |

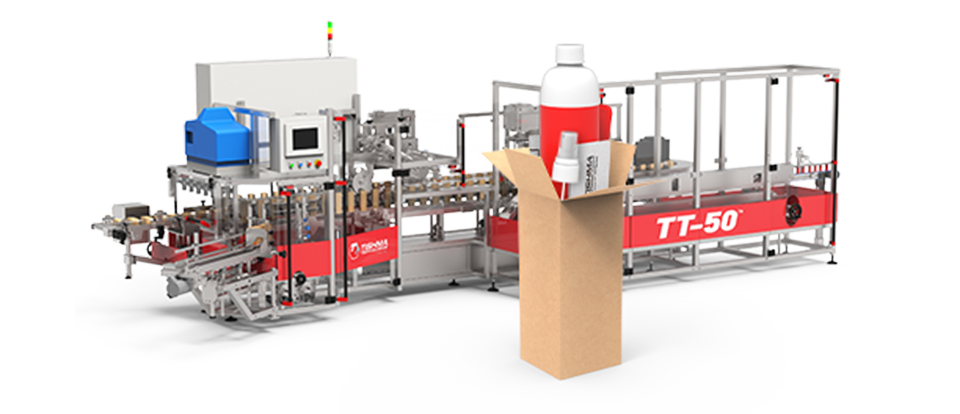

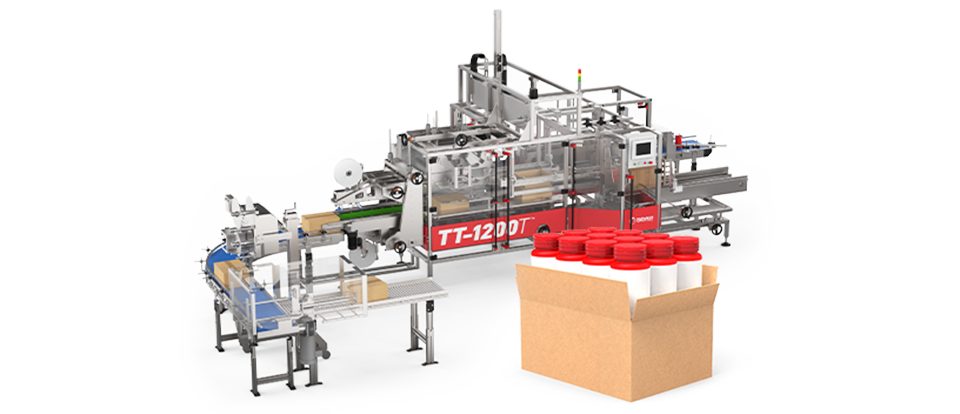

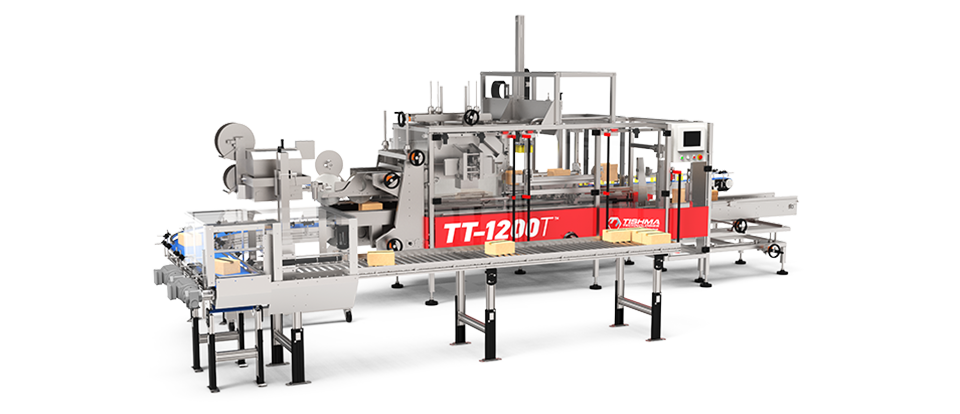

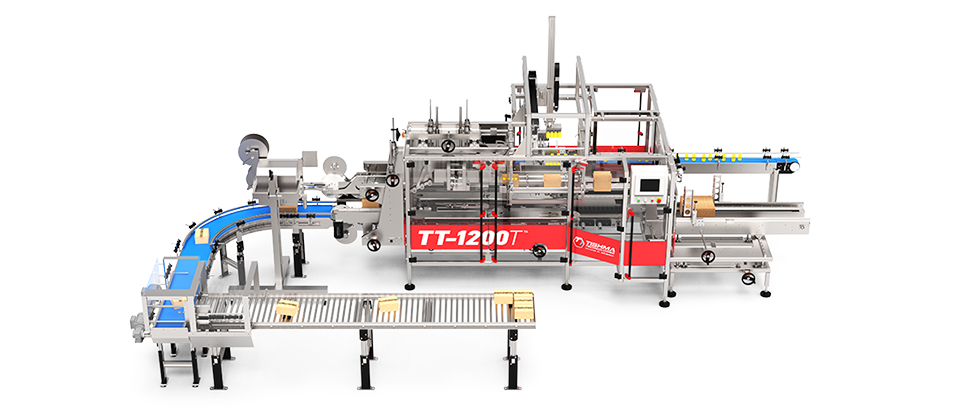

TT-1200 Top-Load Case Packer For Vitamin Bottles

| TYPE | Top Load Case Packer |

| SPEED | Up to 8 CPM |

| MIN. CASE SIZE | 6″ x 4″ x 3″ |

| MAX. CASE SIZE | 18″ x 12″ x 12″ |

| CASE LOADING | Pick and Place System |

| CASE CLOSING | Tape |

| DIMENSIONS | Width: 100″ Length: 168″ Height: 79″ |

| CONTROLS | Allen Bradley PLC/Drive |

| AIR REQUIREMENTS | 12.0 CFM @ 60 psi |

| CASE STYLE | Standard Corrugated Cases, RSC or HSC |

| POWER REQUIREMENTS | 240 Volt, 3-Phase, 60Hz |