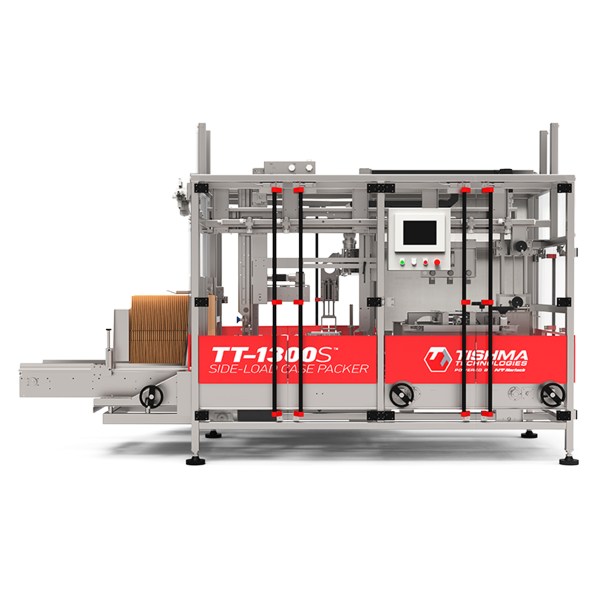

TT-1300S Side-Load Case PackerAutomatic Side-Load Case Packer

The TT-1300S Case Packing Machine provides flexible collation systems and high-speed product handling. Models are available with pre-stacking case conveyors, tape and glue closing, user-friendly HMI operator interface, and small overall footprints. Increase your efficiency with a TT-1300S corrugated case packer with manual, robotic, or collation system case loading.

Literature

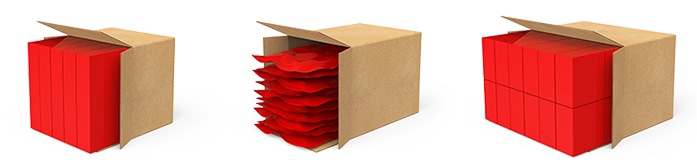

TT-1300S PRODUCT APPLICATION

Cartons ● Boxes ● Pouches ● Cans ● Bags

CASE PACKING MACHINE FOR

CASE PACKING MACHINE FOR

FROZEN MUSSELS VACUUM PACKS

TT-1300S is an intermittent motion Side-Load Case Packer that can reach speeds up to 12 cases/minute. Designed and built for case packing of cartons and non-carton packed products. Ideal for secondary packaging of vacuum-packed foods like seafood, meat and vegetables.

VERTICAL CARTONING / SIDE-LOAD CASE

VERTICAL CARTONING / SIDE-LOAD CASE

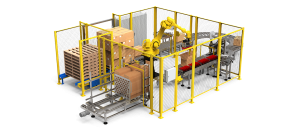

PACKING LINE SIMULATION

The TT-1300 can be integrated with horizontal or vertical cartoners for a fully automated end-of-line solution. Utilize the full potential of Tishma Technologies and invest in an integrated system that provides you with the best, most economical, and highly efficient packaging solutions.

TECHNICAL SPECIFICATIONS

| TYPE | Side-Load Case Packer |

| SPEED | Variable Up to 30 CPM |

| MODE | Intermittent Motion – Manual or fully Automated systems |

| MACHINE CENTERS | 7.5, or 15.0 inches |

| CASE FEED | Powered magazine with reciprocating feeder |

| CARTON LOADING | Manual, Robotic, with Collation System |

| CASE CLOSING | Tape and/or Hot-melt Glue |

| DRIVE | Servo drive, with line shaft |

| CONTROLS | Allen Bradley PLC/Drive |

| FRAME | Welded tubular stainless steel Hinged cover panels with safety electrical interlocks |

| ADJUSTMENTS | Lead screws with calibrated scale references |

| POWER REQUIREMENT | Wired to accommodate your plants electrical requirements |

| AIR REQUIREMENT | Approx. 6.5 CFM 60 psi |