TT-600 Horizontal Cartoner MachineFlexibility Above All

The TT-600 side load cartoner can reach speeds up to 500 CPM, and it is perfect for continuous motion packaging applications. It is available with automatic product transfer, servo-driven collating devices, extended article bucket conveyors, and product confines.

Modular coupon placers, code engravers, or printers make this packaging machine a good solution for labeling as well. Flexo-Tray® models coupled with Smart Loader, Smart Flighter, and Sequential Transfer product handling devices, offer unique benefits and system design flexibility.

Bringing Back Efficiency in Horizontal Cartoning

-

RECEIVING

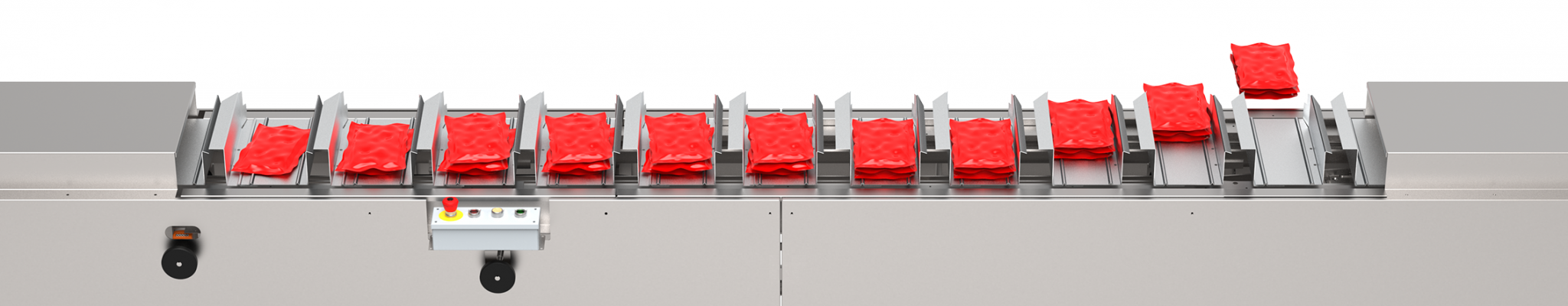

The buckets open to their widest dimension for efficient transfer, gentle product handling and pack pattern flexibility.

-

ORIENTING

The buckets begin to contract, shaping and sizing bags, orienting and aligning pouches, slugs, or other products in single or multiple counts.

-

CONDITIONING

The buckets continue to contract. Articulation may be linear; a single motion, or phased; a series of opposing motions for products that require substantial conditioning.

-

OPTIMIZING

Finally, the buckets adjust to the optimum width for efficient and gentle product loading. From product transfer to carton loading, the sequence is smooth, continuous, and predictable.

FLEXO-TRAY

BRINGING BACK EFFICIENCY IN HORIZONTAL CARTONING

TT-600 side-load cartoning machine represents the new standard of excellence in horizontal cartoning automation. Patented design innovations are best reflected in the Flexo-Tray® models coupled with our Smart Loader. It contains Smart Flighter, Sequential Transfer product handling devices, and it offers unique benefits accompanied by system design flexibility.

TT-600 CARTON STYLES & PRODUCT APPLICATION

Bag-in-a-box ● Long goods ● Pouches ● Stick-Packs ● Frozen Food

TECHNICAL SPECIFICATIONS

| TYPE | Side Load Cartoner |

| MODE | Continuous Motion |

| CANTERS | 1.875″ to 16″ depending upon model |

| SPEED | Variable to 500 CPM, upon model and application |

| CARTON FEED | Powered carton magazine and rotary carton placer |

| PRODUCT LOADING | Article buckets articulate in to carton score lines |

| SENSING SYSTEMS | No product/ no carton and no carton/ no load (with automatic product discharge) |

| CARTON CLOSING | Straight or reverse tuck, or hot melt glue |

| FRAME | Welded tubular stainless steel of open, sanitary design |

| DRIVE | Servo driven with line shaft |

| CONTROLS | Allen Bradley PLC and components |