Cartoner Machine For Hair Product Bottles

The TT-50 cartoner machine for hair product bottles is a continuous motion, semi-automatic vertical cartoner designed and built for top-load cartoning of anti-lice product bottles in cartons. It is perfect for the secondary packaging of bottles containing pharmaceutical, medical or cosmetic products, like shampoos, conditioners, skin cleansing products, make-up removers, hair dye applicators, etc.

A wide assortment of options includes bottle feeders, printers, leaflet placers, visual verification systems, and servo-controlled product handling devices.

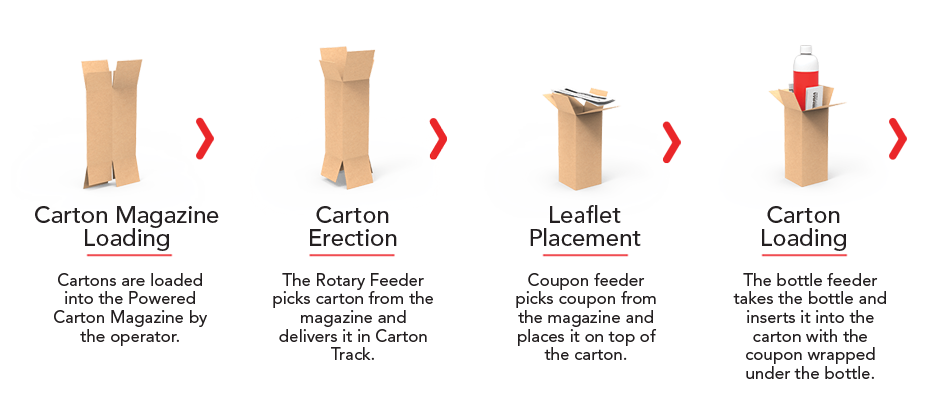

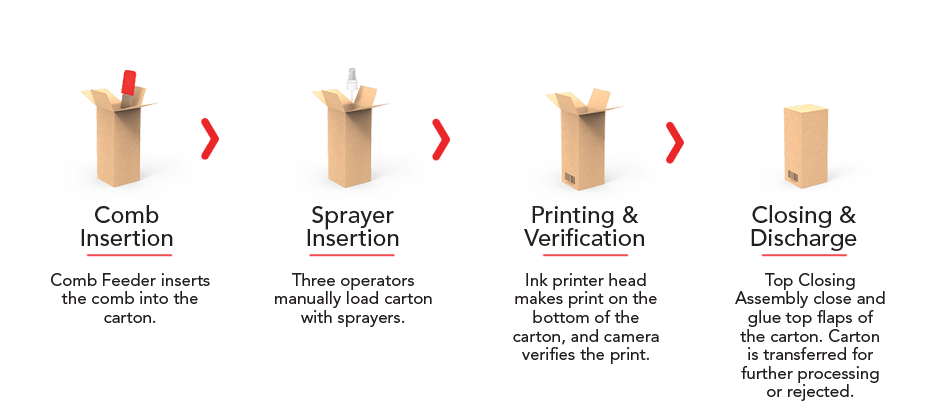

Bottle Cartoning Process

Bottle CARTONING VIDEO

Technical Specifications

| TYPE | Top Load Vertical Cartoner |

| CARTON FEED | Powered magazine with rotary carton feeder |

| SPEED | Up to 140 CPM. Variable to 30 TPM, depending upon application |

| CASE FEED | Powered magazine with reciprocating feeder |

| CARTON LOADING | Automatic bottle loading |

| CARTON CLOSING | Glue Carton Closing |

| TOOLING | Available for tuck, glue, header, gable, flip-top and hex style carton styles |

| CONTROLS | Allen Bradley PLC’s and electrical components |

| SAFETY | Machine guarding with hinged stainless steel framed polycarbonate panels with latches and interlock safety switches |

| OPTIONS | Leaflet feeders, laser or inkjet printers, labellers, tamper evidence, embossers, visual verification and rejection systems |

TT-50 Vertical Cartoner – Operation Overview

The TT-50 cartoner machine for hair product bottles top-load cartoner reaches speeds up to 140 CPM (cartons per minute). Cartons are loaded into the carton magazine by the operator. The rotary feeder picks the carton from the magazine and delivers it into the carton track. Carton travels with carton track and comes to the bottom closing assembly, where the plow system closes and glues the carton’s bottom flaps. The carton with closed bottom comes under the leaflet feeder; the leaflet feeder picks the leaflet from the magazine and places it on top of the carton. The next station is the bottle feeder station. The bottle feeder takes the bottle from the Morrison Timing Screw and inserts it into the carton with the leaflet wrapped under the bottle. The comb feeder inserts the comb into the carton. Three operators load the carton with the sprayer in the manually loading area. A fully loaded carton travels over the printer and vision assembly. Videojet Ink printer head makes the print on the bottom of the carton, and the Cognex camera verifies the print with the help of lights. The top closing assembly closes and glues the top flaps of the carton. The closed carton is laid down onto the discharge conveyor, transferred for further processing, or is rejected in the reject chute.

The TT-50 features stainless steel construction and a simple open design, which allow for easy washdown of all exposed surfaces.

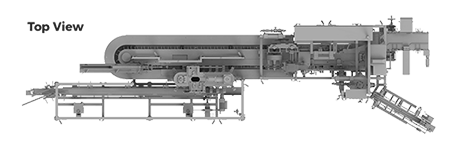

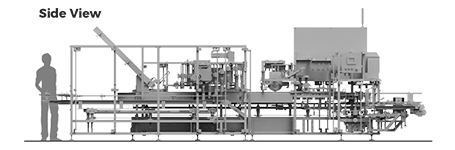

DIMENSIONS & FLOOR PLAN

The TT-50 features an overall compact footprint, so you can rest assured it will fit your floor space.

Reliable and portable with simple operation and a user-friendly interface, TT-50 will be up and running in no time.

TT-50 is a powerful and efficient cartoner that meets the highest standards with state-of-the-art simplicity, built from welded tubular stainless steel with hinged cover panels and safety electrical interlocks.

The TT-50 Cartoner Can Be Integrated With