AUTOMATE WITH ROBOTS

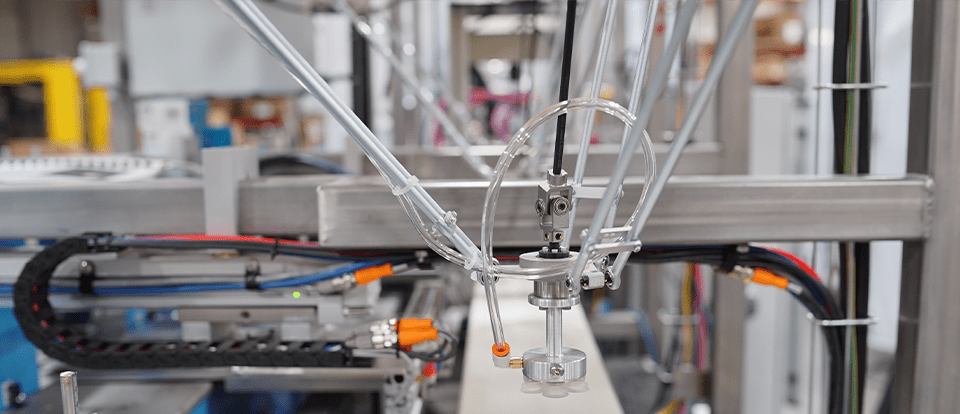

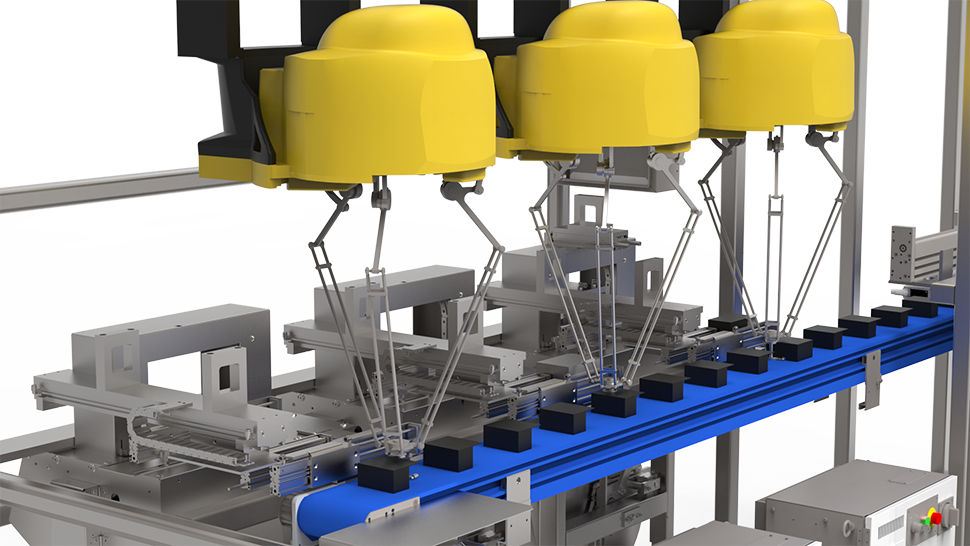

Our vertical and horizontal cartoners can interface with single or multiple robotic cells to accommodate very challenging pack patterns, complex packaging applications, or speed requirements.

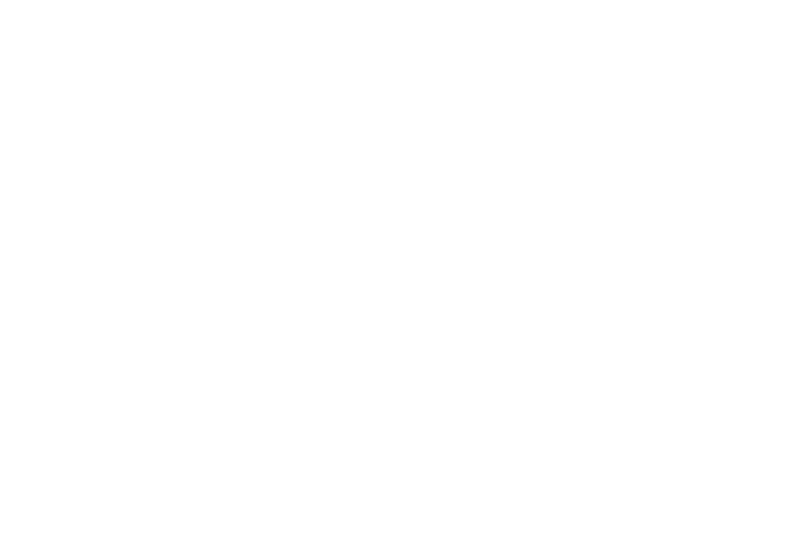

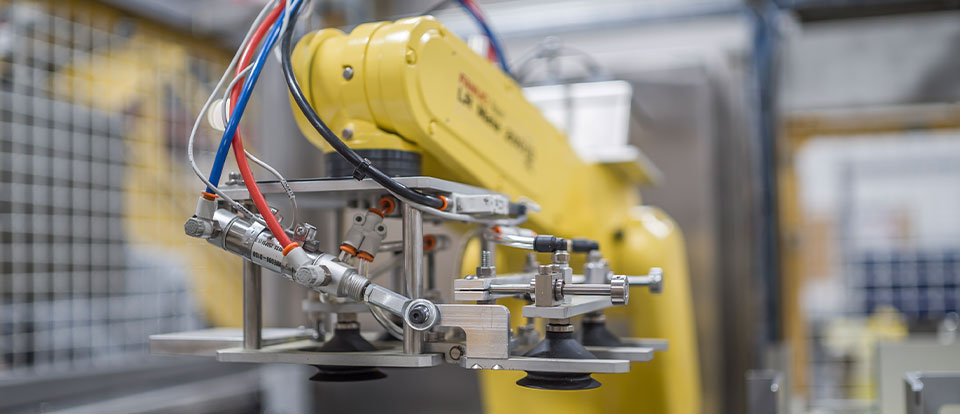

There is a broad spectrum of robotic packaging applications: from automatic case erecting and case loading to palletizing. End-of-arm-tooling (EOAT), gripper, or end-effector components are compatible with your specific packaging application for increased speed and accuracy.

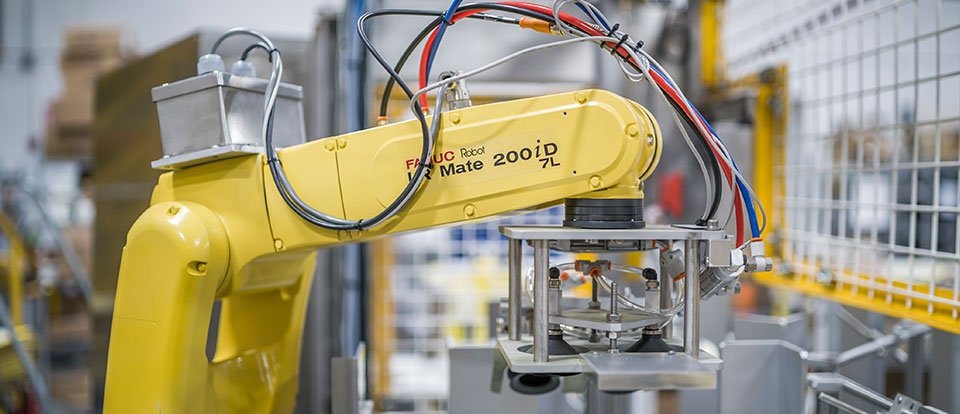

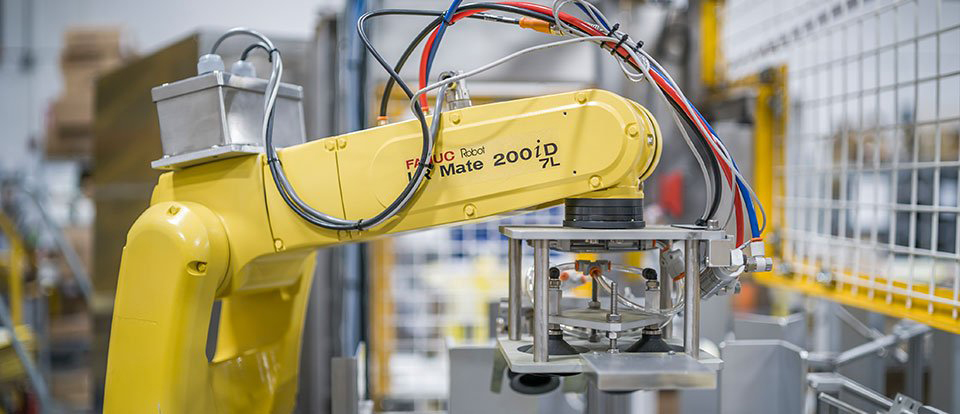

From design and prototyping to integration and maintenance of robotic packaging systems, we can understand and solve any packaging challenge with the help of multi-axis robot arms from industry-leading robot manufacturers like Fanuc, ABB, and Yaskawa Motoman.

Depending on your project needs, we can integrate automatic or manual tool changers to achieve seamless transitions between different robot functions. The most significant advantage robotic packaging systems have over traditional mechanical solutions lies in this kind of versatility.

ROBOTIC BUNDLING

The Raptor and Raptor: R-Series bundling system is a total solution for all your wrapping and banding needs. The benefits and advantages of these bundling packaging machines are easy integration into existing packaging lines and quick bundling of most standard products.

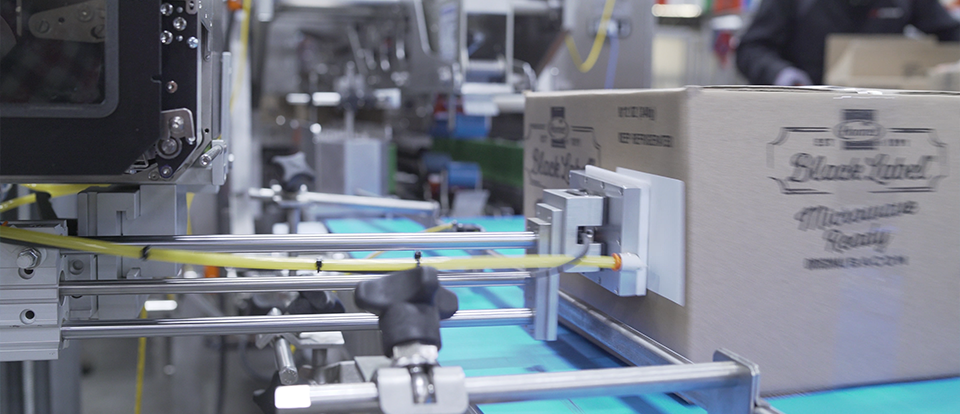

CASE ERECTING

Robotic case erecting is accomplished with the help of a robotic carton erector, which picks the flat case from the magazine, erects the case, and advances it through the hot melt glue closing station for bottom closing.

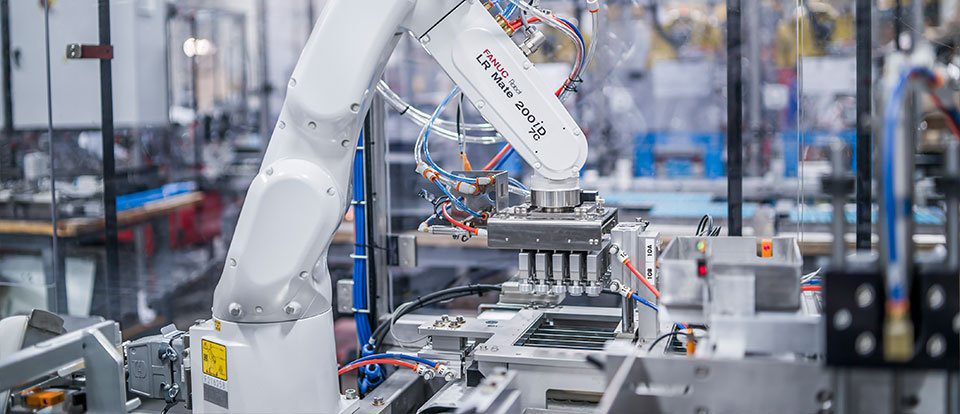

CARTON / CASE

LOADING

The versatile nature of robotic arms allows for fast adaptability to any case loading application. Easily interchangeable grippers provide gentle product handling and the ability to perform multiple functions on multiple lines, even in a single robot configuration. We can tailor your system to any conveyor type and layout.

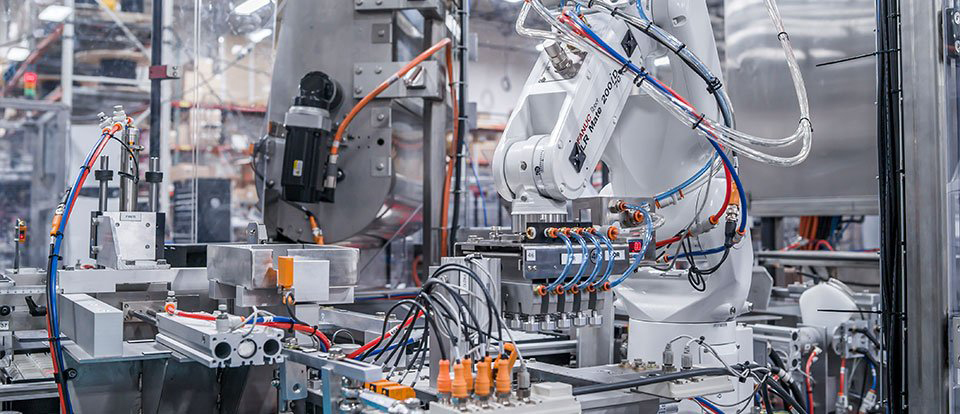

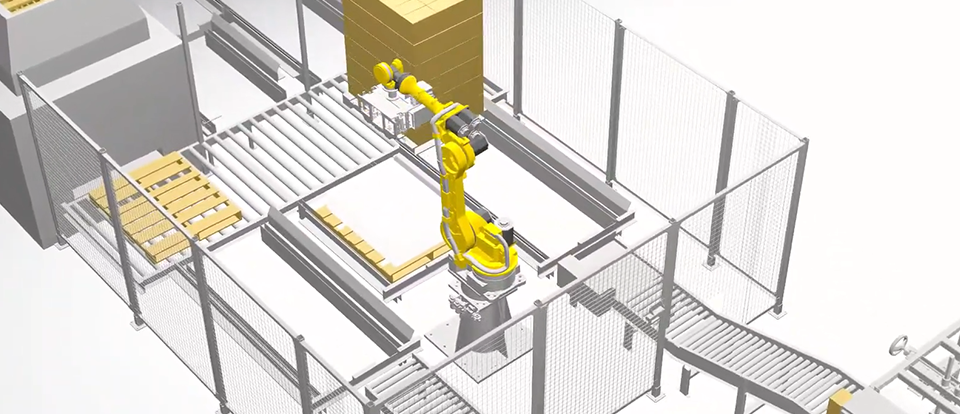

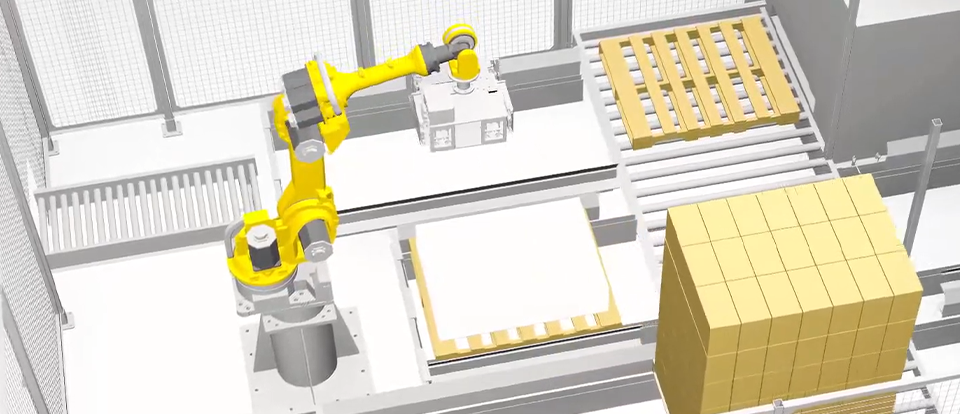

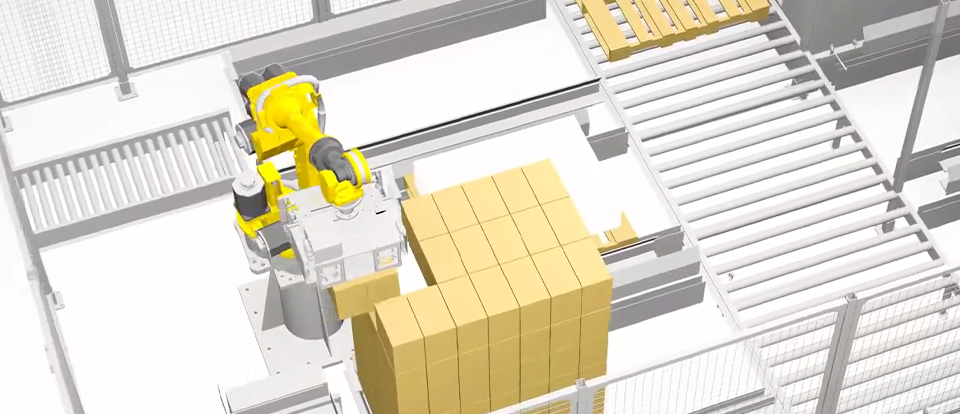

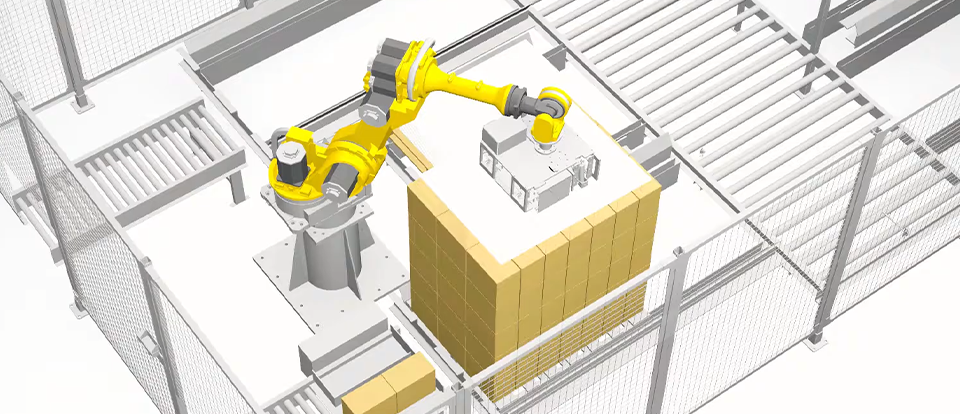

PALLETIZING

We can help you get started with a fully automated end-of-line system. We can integrate Fanuc and Motoman material-handling multi-axis robotic arms known for their speed and reliability. Look no further if you are looking to set up a brand new palletizing operation or rethink your current standard palletizing solution.

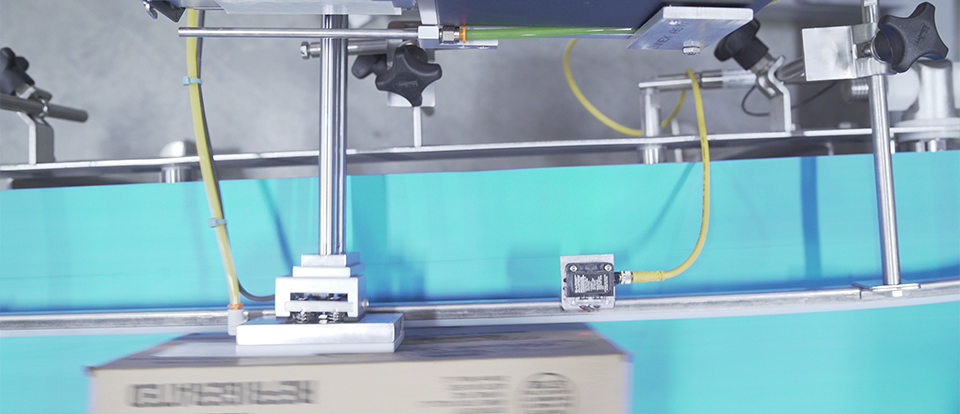

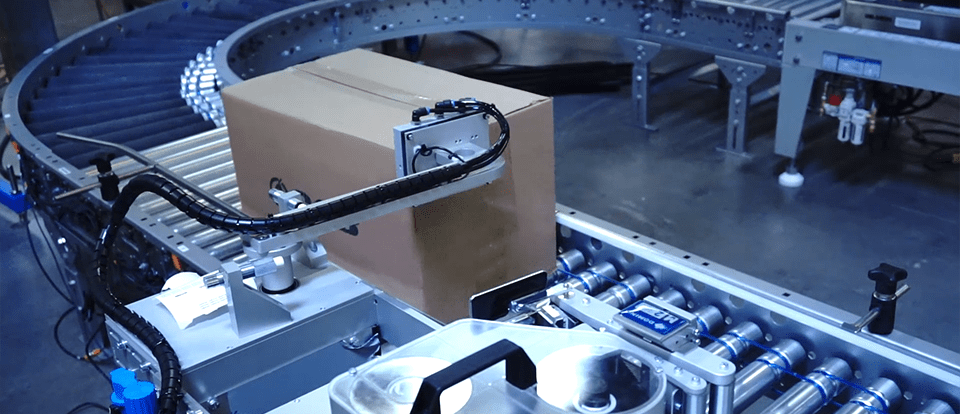

LINE-TRACKING

Track and trace your products with Tishma Technologies’ new visual line tracking software. Line tracking software allows you to optimize your packaging system, and it can be smoothly incorporated into an existing packaging line. Our system also offers a compact solution for track-and-trace palletizers. This solution provides every shipping case with a label containing detailed information about the content of the case.

SIMULATION

Test your solution in the virtual world without spending a cent on hardware or committing to a full-scale build! Before you invest in full system integration, Tishma Technologies can

provide robotic simulation services. With the help of our software, we can very closely emulate the robot’s capabilities and real-world work-cell conditions. We use the data collected during these simulations to improve our understanding of the design for easier

troubleshooting and optimization.

ROBOTIC AUTOMATION CONSULTING

WHY AUTOMATE WITH ROBOTICS?

Robotic Arms can save money, time, and labor. They can bring down the production and test costs. Robotic automation of packaging processes also protects your workers from repetitive motion injuries and allows them to focus on what’s important. However, Robotic Arms need to be properly integrated into your packaging line. To be effective, you need the right end of arm tooling for all packaging applications, along with the right guarding, software, and I/O. In short: you need us.