PALLETIZERS

– ROBOTIC SOLUTIONS –

Whether you search for the robotic, gantry, or collaborative palletizer, Tishma Technologies & Nortech Packaging has the solution for you. All of our competitively priced palletizers feature compact overall footprints, which contributes to significant space-saving. Besides palletizing lines, Nortech Packaging also builds combo packaging lines with robotic case erecting and loading, case closing, labeling and palletizing.

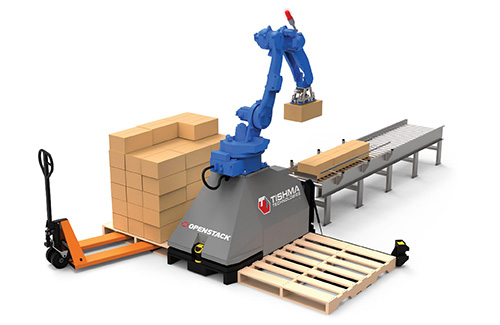

OPENSTACK

ROBOTIC PALLETIZER

The latest trend in robotics is collaborative robots, and Openstack Palletizer is compact and portable, allowing your production to minimize operator involvement and move pallets out the door quickly.

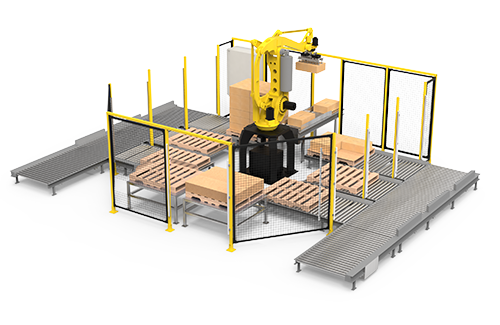

TETRISTACK

ROBOTIC PALLETIZER

Tetristack palletizers feature adjustable infeed heights to match existing conveyors and a platform design that can be transported with a single forklift. Models are equipped with a Pallet loader, full pallet discharge, docking stations for easy locating, integrated forklift inserts, and an adjustable infeed conveyor.