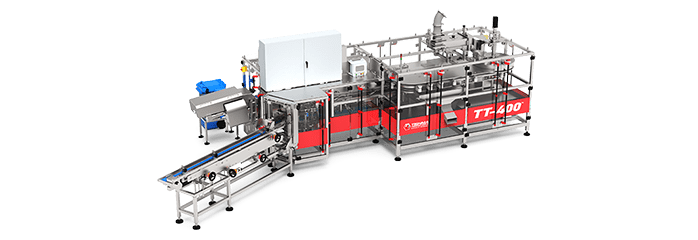

HIGH-SPEED CHEWABLE CANDY VERTICAL CARTONER

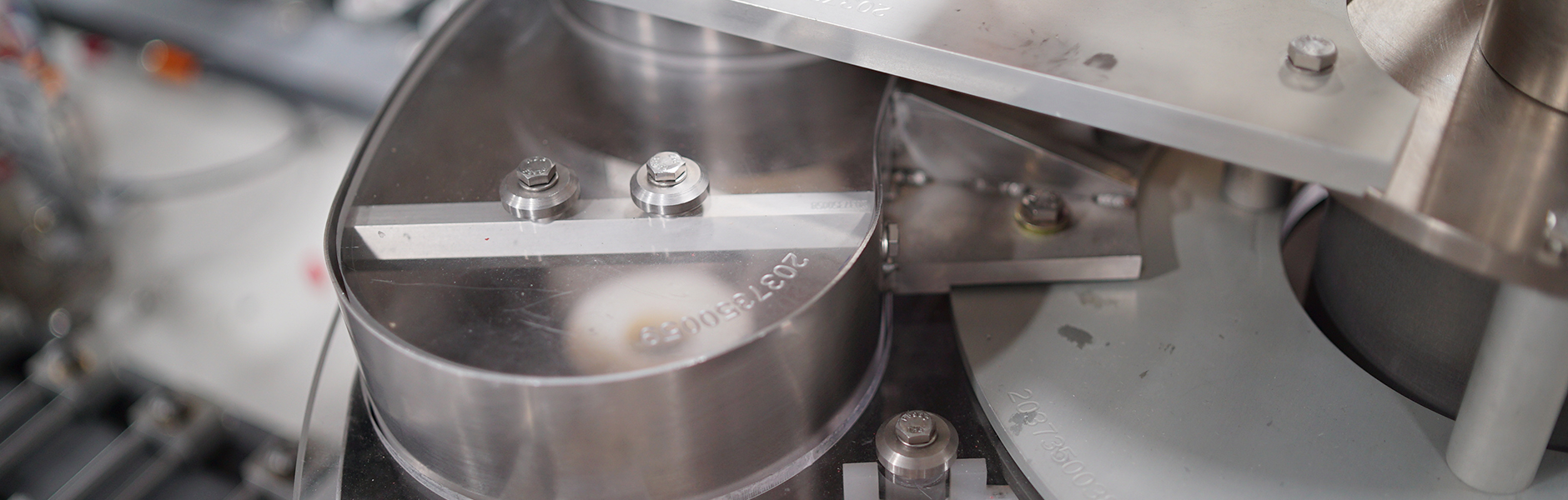

The TT-400 is a continuous motion high-speed top load cartoner that can reach speeds of 600+ cartons per minute. Designed and built for cartoning of free-flowing candy products, it is perfect for primary and secondary packaging of chewing gum, hard candy, dried fruits, and similar products.

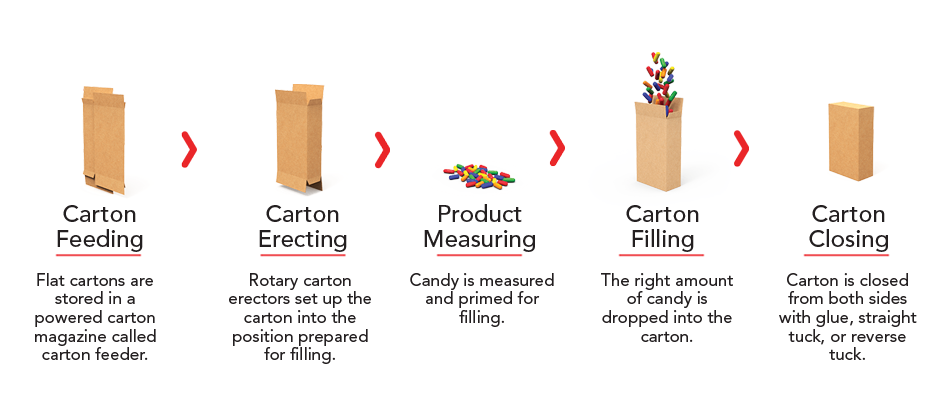

PRODUCT CARTONING PROCESS

TECHNICAL

SPECIFICATION

| TYPE | Top Load Cartoner |

| MODE | Continuous Motion |

| SPEED | 600-750 Cartons Per Minute |

| PRODUCT INFEED | Volumetric Filler and UltraTrack Handling System |

| DIMENSIONS | 204″ x 76″ x 68″ |

| CONTROLS | Allen Bradley PLC |

| DRIVE | Allen Bradley Servo Motor, Line Shaft |

| POWER REQUIREMENTS | 480 V, 3 Phase, 60Hz |

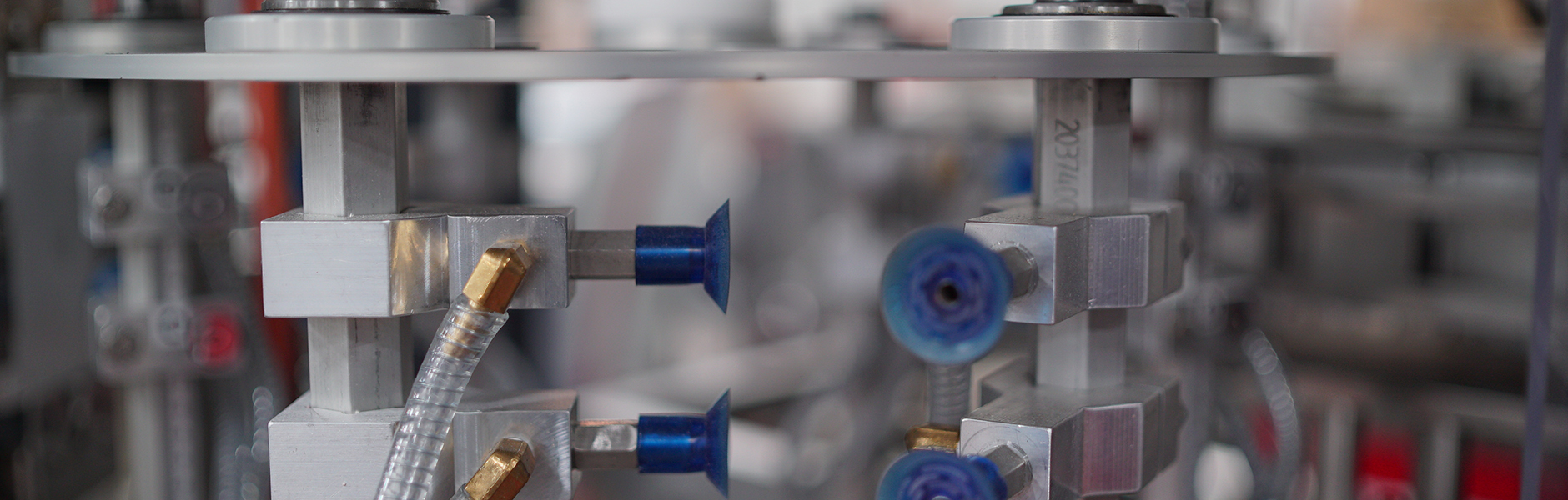

| AIR REQUIREMENTS | 12.0 CFM @ 60 psi |

| CARTON STYLE | Theater Box, Standard Glue-Sealed Carton |

TT-400 HIGH-SPEED TOP LOAD CARTONER

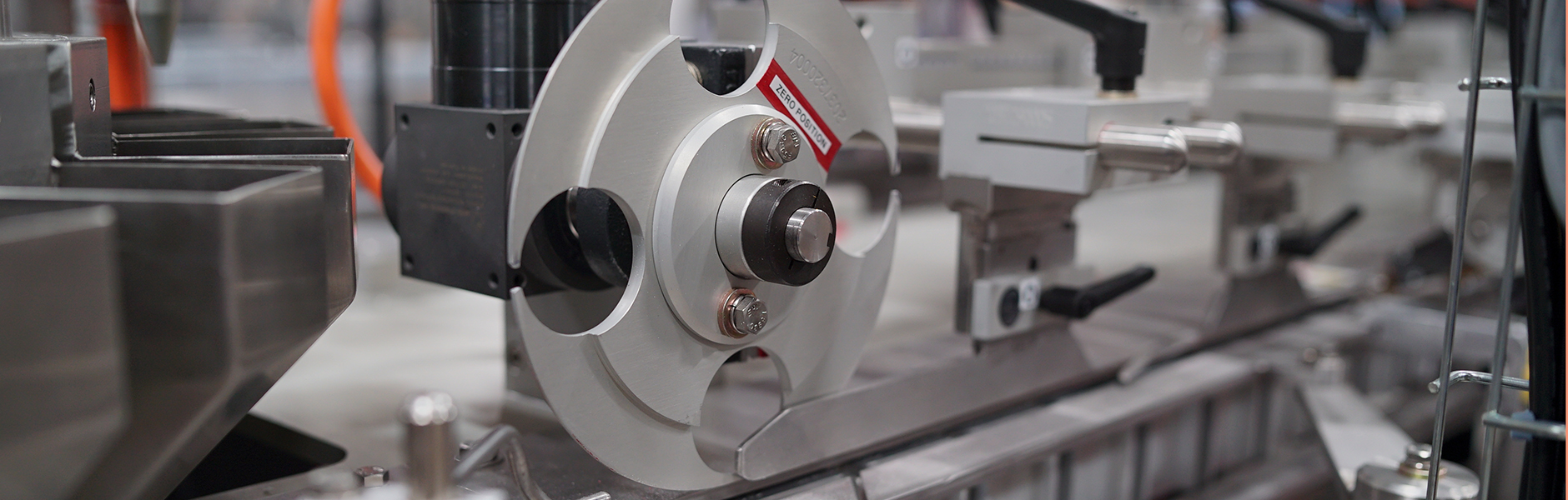

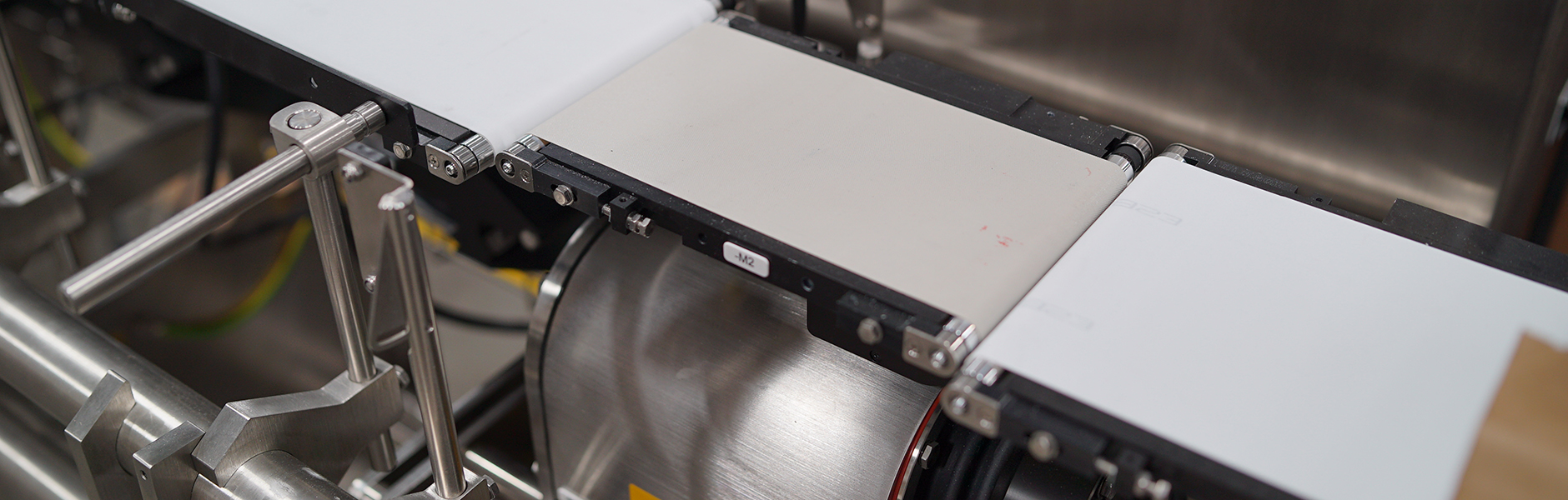

This high-speed top load cartoner supports multiple carton sizes and features easy changeover. The TT-400 features a Patented UltraTrack high-speed volumetric cup filler that provides no-carton/no-product, no-product/no-carton functionality. Stainless steel construction and simple, open design allow for easy washdown of all exposed surfaces.

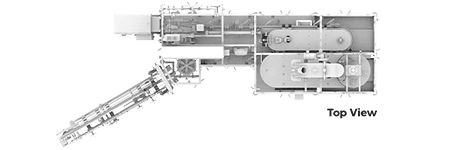

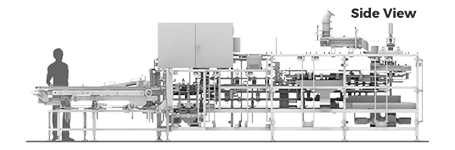

DIMENSIONS & FLOOR PLAN

TT-400 features an overall compact footprint, so you can rest assured it will fit your floor space.

Reliable and portable with simple operation and a user-friendly interface, TT-400 will be up and running in no time.

TT-400 is a powerful and efficient cartoner that meets the highest standards with state-of-the-art simplicity, built from welded tubular stainless steel with hinged cover panels and safety electrical interlocks.

CAN BE INTEGRATED WITH

CASE PACKERS

Tray packers